Quality Control

Cracking Concrete SurfacesWhat is concrete cracking?

Concrete is a construction material that expands and contracts with the changes in moisture and temperature. Cracks may occur when provisions to accommodate these movements are not made in design and construction. Most random cracks that may appear at the concrete's early age rarely affect the structural integrity or the surface life of concrete. Why do concrete surfaces crack? The vast majority of concrete cracks usually occur due to improper design and construction practices. Rules to minimize concrete cracking:

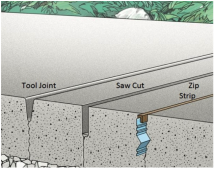

Joints in Concrete Slabs on GradeWhat are joints?

As mentioned above, concrete expands and contract with changes in temperature and moisture, which can cause early cracking. Joints are simply pre-planned cracks. Joints in concrete slabs can be created by forming, tooling, sawing, and placement of joint formers. Why are joints created? Joints provide relief from the tensile stresses, are easy to maintain and are less objectionable and uncontrolled than irregular cracks. Rules for proper jointing:

|

Curing In-Place ConcreteWhat is concrete curing?

Curing is the maintaining of an adequate moisture content and temperature in concrete at early ages so that it can develop properties the mixture was designed to achieve. Curing begins immediately after placement and finishing so that the concrete may develop the desired strength and durability. Why cure? There are four important reasons to cure your concrete: predictable strength gain, improved durability, better serviceability and appearance. How to cure: Concrete should be protected from losing moisture until final finishing using suitable methods to avoid plastic shrinkage cracking. After final finishing the concrete surface must be kept continuously wet or sealed to prevent evaporation for a period of at least several days after finishing. Crazing Concrete SurfacesWhat is crazing?

Crazing is the development of a network of fine random cracks or fissures on the surface of concrete or mortar caused by shrinkage of the surface layer. Typically craze cracks develop at an early age and are apparent the day after placement. They do not affect the structural integrity of concrete and rarely affect durability or wear resistance. Why do concrete surfaces craze? Concrete surface crazing usually occurs because one or more of the rules of "good concrete practices" were not followed. Rules to prevent crazing:

|